Could you describe to me the beginning of the Circle Sportswear adventure?

Romain: I have had a passion for as long as I can remember, which is sports. I've done cross country, skiing, tennis. Sport has fueled my life and it accompanies my daily life. I am also passionate about economics and I am very interested in the circular economy. That's why I wanted to get into this.

I've traveled all over the world, and my travels made me realize how much our landscapes were hit by plastic and microplastic pollution.

When I returned to Paris one day, I started running. As I opened my wardrobe, I realized that my sports products were the complete opposite of the rest of my clothes: made on the other side of the world, materials derived from plastic itself derived from oil...

To me, it seemed super contradictory: all great sportsmen are committed to nature, especially those who practice an outdoor sport. Yet our sports equipment doesn't fit into that at all.

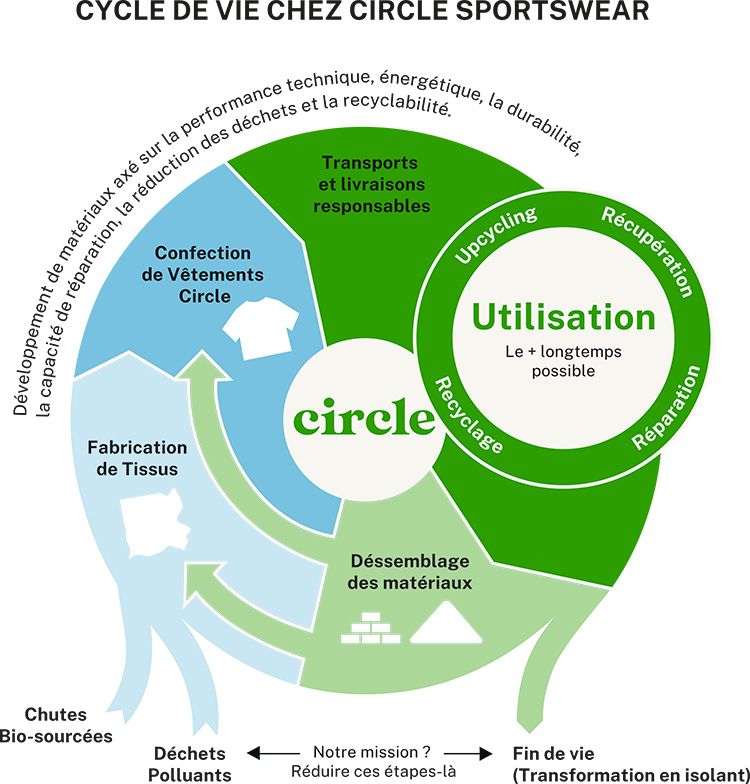

The fundamental principle of Circle is to have closed-loop eco-designed sports products. We make sure we have an eco-design upstream of production, and we build a rigorous set of specifications. We also manufacture our products in Europe.

Circularity is at the heart of your brand, can you describe this circular journey from sourcing of materials to end of life of the products?

Romain: This circular approach has been implemented gradually. The Circle product must last over time, so the priority is to think upstream about the product's end of life. The goal is to activate end-of-life solutions as late as possible, meaning that the product must last a very long time.

One of the solutions is to repair the product. We are currently working on end-of-life management, which will be launched in the coming months, during March 2023. Our goal is to develop a circular offer at the end of life, to encourage our community to take action and participate in this circular economy. In exchange, our customers will be able to receive a discount on a future product with us.

We are also thinking about offering our customers to give back a certain amount to associations with whom we partner. Since we are a company with a mission, this is important to us. We work with associations with an environmental goal and with a goal of reintegration of young people through sports.

You have the Cradle to Cradle label, can you present this label to us in more detail?

Romain: It is a label integrating both the eco-design and environmental ethics part. The idea is to make sure that everything we use at the beginning of our production, goes back to where it came from.

At Circle, all of the materials we use are recycled materials (plastic bottles recovered from around the garbage dump). At the end of life, we have a recycling solution.

This is a principle that avoids polluting by reusing our resources. It's a collective challenge we have to lead, and Circle aspires to be a pioneer in this.

You produce in Portugal and source materials from the European Union. Can you tell us more about your workshops, environmental and social dimensions?

Romain: What is important is traceability and transparency. We have identified all the stakeholders in the manufacturing of our products.

We oblige ourselves to make sure that all components come from Europe. That's why it took so long for the basketball to come to Circle: it's an area that is being reindustrialized in Europe.

There are two reasons for European production.

First of all, a corporate name. The companies we work with have social commitment programs in place, mandatory minimum wages, right to unemployment, health insurance, and maximum working time law. This is absolutely huge compared to the whole industry, especially in Asia. When you produce in Europe, you can check that labor rights and employee welfare are respected.

We often go and audit the workshops to make sure everything is going well. We want to meet with the shop floor employees and we want them to understand the meaning of what we're putting in place.

Recently, we did a collaboration with Alexandra Rosenfeld, who is a committed yoga teacher. We went to one of our factories and offered a yoga class to employees. It sounds harmless like that, but this class did them a lot of good, knowing that factory jobs today are still pretty tough. We continued to talk with them afterwards so that they could incorporate yoga into their routine if they wanted to.

Then there is an environmental reason.If we take dyeing, all the products used in Asia are banned in Europe. On materials, it is very difficult to ensure that you really order a recycled material. However, in Europe, we have complete traceability.

And finally, one of the issues that is often forgotten even though it is crucial is the energy mix used to manufacture the products. In running shoes, 75 % the carbon impact of the shoe comes from the energy mix!

The majority of running shoes are made in Vietnam or China, where the energy is composed of more than 95 % coal. While in Europe, the production of shoes depends on "carbon neutral" energy. It's not obvious, but that's what really counts and that's what we need to do if we want to reduce our emissions.

There is also transportation. By producing in Europe, we are less than 1200 km from our factories. We stay in France, Portugal, Spain, Italy and Austria. This corresponds to about 3 to 6 % of the carbon impact of the product.

Finally, we also refuse to transport by boat, because freight boats participate in the destruction of the marine ecosystem.

Can you tell us more about your eco-responsible materials, especially Tencel?

Romain: We use Lyocell (which is also called Tencel) that we mix with biodegradable elastane. We use it on all ranges of sweatshirts, t-shirts, including the get lucky capsule. It's innovative, it gives a unique feeling. It is a light, stretchy, naturally thermo-regulating fabric: all the properties needed for sports!

We created a specification for this fabric, which needs to be more eco-friendly, efficient, and design-friendly.

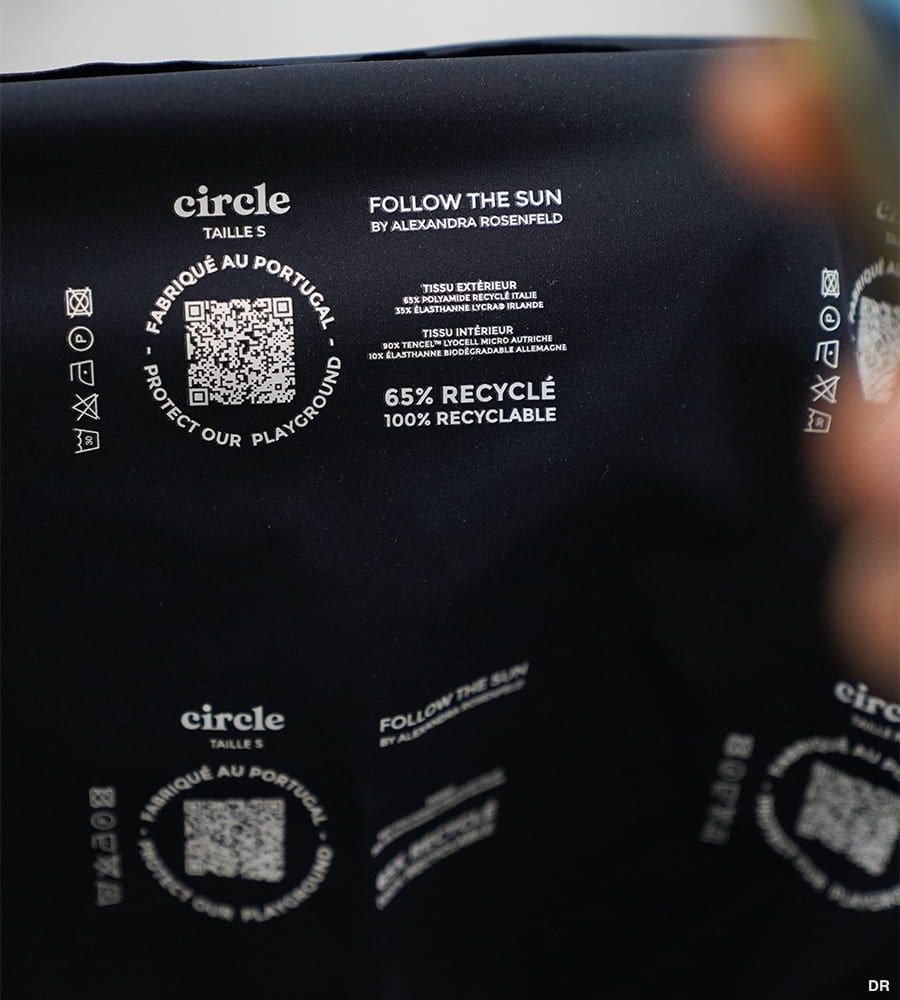

You are committed to more traceability, can you tell us about the QR code on your clothes, which allow the consumer to learn about the origin of his product and its recyclability characteristics?

Romain: At the beginning of Circle, we asked ourselves the following question: where to put the label? Then we asked ourselves why it was necessarily necessary to put a label on every product.

That's when we thought we could just put the mandatory elements on the garment, and other information on a QR code. There is already a logic of eco-design, that is, we do not want to add unnecessary materials.

But there is also a role of awareness: the QR code allows the customer to learn about the origins of his product. It's a bit like a product passport. You can see the materials used, where the products were made, their environmental impact, certifications, and maintenance tips that teach the customer to make the product last as long as possible.